Titanium / Titanium alloys (β-Ti, β-Ti+α) Tubing, Capillary / Wire / Rod / Sheet

Seamless Titanium Tubing, Capillary / Wire / Rod / Sheet

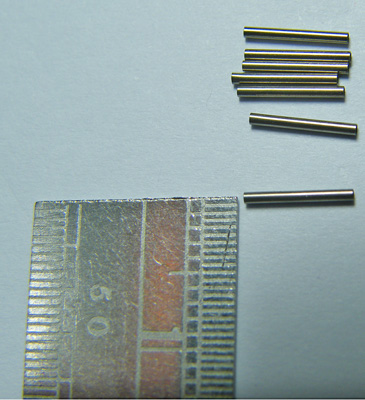

(please Click photo for details)

Seamless Titanium / Titanium alloys (β-Ti, β-Ti+α) Tubing, Capillary / Wire / Rod / Sheet

M&T's Titanium Specifications:

|

Titanium Tubing |

Titanium Wires |

Titanium Solid Rods |

Titanium Sheets |

|

Grade 1, 2, 5, 9, 12, 23, β Titanium alloys |

Grade 1, 2, 4, 5, 9, 12, β Titanium alloys |

Grade 1, 2, 5, 7, 9, 12, 23, β Titanium alloys |

Grade 1, 2, 5, 7, 9, 12, β Titanium alloys |

|

O.D. in mm: Ø0.5mm~Ø6.35mm~ Ø305mm Thickness in mm: 0.05mm~1.5mm~15mm |

O.D. in mm: Ø0.05mm~Ø2mm |

O.D. in mm: Ø2mm~Ø305mm

|

Thickness in mm: 0.025mm~50mm |

|

Length Cut in mm: 5mm~23000mm |

In Coils or Scrolls |

Length Cut in mm: 5mm~23000mm |

Length and Width Cut in mm: 5mm~1000mm~ L

|

|

ASTM B337, B338, B861, B862, F67, F136, F1295 |

ASTM B863, F67, F136, F1295 |

ASTM B348, F67, F136, F1295 |

ASTM B265, F67, F136 |

Extra Processes: Annealing ; Surface treatments with electrolysis, polishing, anode, black oxidized, pickling and so on.

※Titanium / Titanium alloys (β-Ti, β-Ti+α) Tubing, Capillary / Wire / Rod / Sheet products comply with RoHS's the most updated directives and comply with the standards of ASTM B337, ASTM B338, ASTM B861,ASTM F 67 and etc. RoHS reports tested by institutes-SGS, AOV, CTI are available on demand. Mill sheet, data sheet and inspection certificate are available per order.

Manufacturer complies with ISO 9001:2008, excellent capacity and short lead-time. Customized project, Drawing and Inquiry are the most welcome!!!

M&T's Titanium Capillaries on Medical applications are: Biliary Stent, Coronary Stent, Heart Stent, Cardiovascular Stent. Titanium Needle Gauge #7~#25, Bone Screws, Bone Plates, and so on.

|

1.Grade 1: the most ductile and softest titanium alloy. Act excellent for cold forming and corrosive environments.

2.Grade 2: Unalloyed titanium, standard oxygen.

3.Grade 5: also known as Ti6Al4V, Ti-6Al-4V or Ti 6-4, the most common used. It’s chemical composition of 6% aluminum, 4% vanadium, 0.25% (maximum) iron, 0.2% (maximum) oxygen, and titanium the balance. It’s a lot stronger than commercially pure titanium in the same stiffness and thermal properties (excluding thermal conductivity, which is about 60% lower in Grade 5 Ti than in CP Ti). This grade is heat treatable to be an excellent combination of strength, corrosion resistance, weld and fabricability.

4.Grade 7: contains 0.12 to 0.25% palladium. This grade is similar to Grade 2. The small quantity of palladium added gives it enhanced crevice corrosion resistance at low temperatures and high pH.

Grade 7H: is identical to Grade 7 with enhanced corrosion resistance.

5.Grade 9: contains 3.0% aluminum and 2.5% vanadium. This grade acted between the ease of welding and manufacturing of the "pure" grades and the high strength of Grade 5. It is commonly used in aircraft tubing for hydraulics and in sports equipment.

6.Grade 12: contains 0.3% molybdenum and 0.8% nickel, excellent corrosion resistance in reducing and oxidizing environments and offers better heat resistance than pure titanium grades. It is suitable for applications such as shell and tube heat exchangers and is typically used within the chemical industries.

7.β Titanium alloys: Titanium mix with Betastabilizers (ex:Chromium, Nickel, Copper, Silicon, etc.) and have excellent formability and can be easily welded. Major consumptions are on orthodontics and dental appliances.

Note:

※α Titanium alloy contains(Alpha stabilizers): Aluminum, Tin, Gallium, Germanium, Carbon, Oxygen, Nitrogen.

※β Titanium alloy contains (Betastabilizers):Molybdenum, Vanadium, Tantalum, Niobium, Manganese, Iron, Chromium, Cobalt, Nickel, Copper, Silicon,Tantalum, Zirconium.

※Titanium Grades 1,2,3,4,7,11,12 are classified as unalloyed/commercially pure.